n the world of pharmaceuticals and dietary supplements, the methods of delivery play a critical role in the efficacy and popularity of the product. Two of the most common forms are capsules and tablets. Understanding the manufacturing insights behind these options can help businesses and consumers alike make informed decisions. This blog post will explore the differences between capsule filling and tablet compression, offering insights into each process, their benefits, and their challenges. Whether you’re a supplement copacker or a curious consumer, this guide will provide valuable insights.

Understanding Capsules and Tablets

Capsules and tablets are popular delivery methods for active ingredients in pharmaceuticals and supplements, each with unique characteristics. Capsules are gelatin or plant-based containers that are easy to swallow and can mask unpleasant tastes, while tablets are solid forms created by compressing powders, often coated for easier swallowing and ingredient protection. Understanding these differences is essential for manufacturers to choose the best option for their products and market.

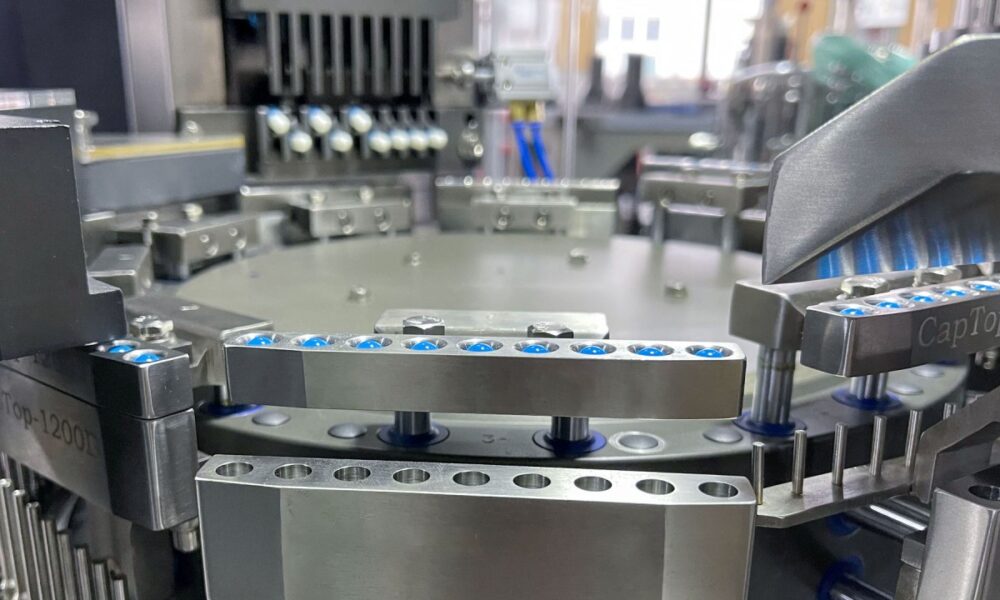

The Basics of Capsule Filling

Capsule filling is a versatile and efficient process that ensures accurate delivery of active ingredients. It involves carefully measuring and mixing raw materials, filling empty capsule shells, sealing them, and conducting quality checks for consistency. This method accommodates various fill types, such as powders, granules, or liquids, making it ideal for manufacturers delivering complex formulations.

Exploring Tablet Compression

Tablet compression is a cost-effective process that combines ingredients into solid tablets through pressure, making it suitable for large-scale production. The mixture is compressed into specific shapes and sizes, with pressure influencing hardness and dissolution rates. Tablets are often coated for protection, appearance, and controlled release of active ingredients. This method ensures reliable, consistent products with extended shelf life.

Benefits of Capsule Filling

Capsule filling offers significant advantages for both manufacturers and consumers, including the ability to combine multiple ingredients in one dose, improved bioavailability, and easier swallowing due to their smooth surface. Capsules can also mask unpleasant tastes, enhancing the consumer experience. These features make them a flexible and user-friendly option for product design.

Advantages of Tablet Compression

Tablets are a popular choice for manufacturers due to their cost-efficiency, precise dosing, and enhanced stability. Tablet compression is often more economical than capsule filling, making it ideal for large-scale production. Additionally, the coating process protects active ingredients from moisture, ensuring consistency and prolonging shelf-life, making tablets a reliable solution for high-volume production.

Challenges in Capsule Filling

Capsule filling offers advantages but also presents challenges, such as ingredient incompatibility that can affect stability and efficacy. Materials like gelatin may not suit all consumers, leading to the need for more expensive plant-based alternatives. Additionally, strict quality control is necessary to ensure proper filling. Addressing these issues is crucial for manufacturers to uphold product quality and maintain consumer trust.

Considerations for Tablet Compression

Tablet compression is an efficient but challenging process that requires precise pressure control to prevent defects like cracking or chipping. The selection of compatible excipients is crucial for maintaining stability and effectiveness, while the dissolution rate must be consistent to ensure the tablet’s efficacy and consumer satisfaction. Careful formulation and testing are essential to overcome these challenges and produce a high-quality product.

Key Differences Between Capsules and Tablets

Understanding the differences between capsules and tablets helps manufacturers select the best form for their products. Capsules are flexible and easy to consume, ideal for complex formulations, while tablets are cost-effective with precise dosing and longer shelf life. The choice depends on the product’s use, target market, and production scale, as each offers unique benefits that can enhance appeal and effectiveness.

Factors Influencing Manufacturing Decisions

The choice between capsule filling and tablet compression is influenced by factors like the type of active ingredients, desired release profile, and target audience. Manufacturers must weigh production costs, scalability, and regulations, as capsules may provide flexibility and appeal, while tablets often offer cost-effectiveness and stability. Balancing these considerations is essential for creating a successful product that fulfills both manufacturer and consumer needs.

Innovations in Capsule and Tablet Manufacturing

The pharmaceutical and supplement industries are advancing in capsule filling and tablet compression, thanks to technological innovations. Liquid-filled capsules and enteric coatings enhance bioavailability, while 3D printing and continuous manufacturing improve dosing precision and production speed. Staying updated with these developments helps manufacturers stay competitive and deliver innovative products.

Conclusion The Best Form for Your Product

Capsule filling and tablet compression each have unique benefits and challenges. The choice between them depends on factors like formulation, target audience, and production goals. Capsules are flexible and user-friendly, while tablets are cost-effective and offer precise dosing. Understanding these options helps manufacturers create products that meet market demand and exceed consumer expectations, ultimately distinguishing them in a competitive industry.